|

Forging presses - Press technology | Ortlinghaus

Mechanical forging presses with flywheel drive are suitable for the mass production of forging parts. Ortlinghaus provides a wide range of products for mechanical forging presses, such as clutch-brake units, complete press drives and separate wet-running clutches and brakes. Ortlinghaus is the only manufacturer of plates who is able to deliver very large dimensional plates for clutches with a torque range of up to 1.4 million Nm.

Main drive - Forging presses

Main drive locking clutch | Series 055

Transferring press ram weight to press frame at stationary press

According to DIN EN 692, the relevant safety standards for press engineering, a mechanical restraining device must be present in mechanical presses for repair work and work between the two halves of the tool.

The Ortlinghaus linear motion lock from the series 055 is an approved restraining device according to the German employers' liability insurance association. The linear motion lock is used to positively lock a shaft to the fixed housing of a clutch so that the shaft cannot rotate. This is particularly desirable for presses to ensure that the press ram will not move in an uncontrolled or unintended manner during servicing or maintenance work between the two halves of the die.

The Ortlinghaus ram locking mechanism enables a variable locking of the press ram in any position, with a short actuating time. The linear motion lock is matched to and integrated into the machine's drivetrain. It is engaged or disengaged hydraulically. The state of the ram locking mechanism actuated by oil pressure, either locked or unlocked, is detected using inductive travel sensors and transmitted to the machine control unit.

- Torque: 11,000 - 100,000 Nm

- Outside diameter: 480 - 900 mm

- Bore diameter: 120 - 260 mm

- Length: 195 - 325 mm

|

|

|

|

Rotary inlet | Series 086/087

Ortlinghaus has been manufacturing single and multi-channel rotary inlets for several decades and these are frequently supplied as accessories for air and oil actuated and also for oil cooled clutches. These tried and tested machine components for the feeding of air, pressurised oil and cooling oil into rotating shafts are standard products and are not only for use in conjunction with clutches.

In addition to this Ortlinghaus also develops and manufacturers rotary inlets to customers own requirementswhich cannot be met from standard products listed in the catalogue. It is thus possible for example to manufacture rotary inlets with up to eight channels with the channels being able to carry different media (air / oil; air / water).

|

|

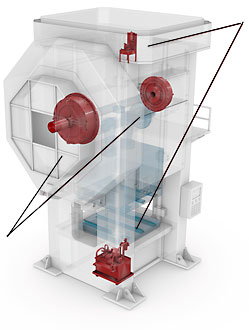

Hydraulical clutch-brake unit | Series 123

Wet-running, hydraulically actuated, high thermal load allowed

The hydraulically actuated clutch-brake units from the series 123 work exclusively with wet-running, oil-cooled plates with friction pairing steel/sinter.

The advantages of having a multi-plate construction and oil-cooled friction pairing steel/high-performance sinter in addition to actuation with pressure oil at 60 bar are seen in the product’s extraordinarily compact design and high operating efficiency. The series offer high torque, low moment of inertia and high switching speeds with a minimal need for maintenance. Model series 123 represent a good alternative to dry-running combinations. They operate in sealed housings which prevent leakage and keep switching noise to a minimum.

With these benefits, the clutch-brake units are suitable for a broad range of applications in press, shear press, and large press engineering as well as in embossing presses and drawing presses. The series was designed and constructed according to international safety regulations and approved by the German employers’ liability insurance association.

- Torque: up to 630,000 Nm

- Rotations per minute: 350 - 1,700 min-1

- Outside diameter: 199 - 1,180 mm

- Bore diameter: 58 - 375 mm

- Length: 135 - 650 mm

|

|

|

|

Hydraulic clutch | Series 127

Acceleration of press ram in single-stroke mode

Hydraulically actuated clutches and brakes work exclusively with “wet-running” oil-cooled plates with the friction pairing steel/sintered lining. The advantages of actuation with pressure oil at 80 bar, the multi-plate construction type and the oil-cooled friction pairing steel/high-performance sinter result in an exceptionally compact design with high performance.

They feature high torques, low mass moments of inertia, high switch times and little maintenance. The separate design requires different shaft ends for installation, which makes it possible to use different clutch and brake sizes. Since they run in a sealed housing, no dirt is released into the environment.

The international safety regulations for press manufacture were taken into consideration for the design. The clutch-brake combinations have been recognized as safe by the German Employers’ Liability Insurance Association and type-tested by the Swedish Industrial Safety Authority.

- Torque: up to 1,400,000 Nm

|

|

|

|

Hydraulic brake | Series 128

Deceleration of press ram in single-stroke mode

Hydraulically actuated clutches and brakes work exclusively with “wet-running” oil-cooled plates with the friction pairing steel/sintered lining. The advantages of actuation with pressure oil at 80 bar, the multi-plate construction type and the oil-cooled friction pairing steel/high-performance sinter result in an exceptionally compact design with high performance.

They feature high torques, low mass moments of inertia, high switch times and little maintenance. The separate design requires different shaft ends for installation, which makes it possible to use different clutch and brake sizes. Since they run in a sealed housing, no dirt is released into the environment.

The international safety regulations for press manufacture were taken into consideration for the design. The clutch-brake combinations have been recognized as safe by the German Employers’ Liability Insurance Association and type-tested by the Swedish Industrial Safety Authority.

- Torque: up to 1,400,000 Nm

|

|

|

|

Press control - Forging presses

Control units | Series 086 - 392

- Fast filling and draining of the piston chamber of the clutch-brake unit

- Control of the clutching and breaking function of the clutch-brake unit

- Including safety valve

|

|

|

|